Forum for the Future Kick-Off Breakfast Part II

The second speaker for the Forum for the Future Kick-Off Breakfast was brilliant! Alex L Goldfayn CEO, Evangelist Marketing Institute gave a very memorable presentation geared toward increasing your profits with simple, no-cost marketing strategies. Alex was very engaging and had the personality and the material to give a much longer speech.

He stressed the point that most everyone in the room had products and services that are more than good enough to grow revenue significantly, meaning if you didn’t improve your products or services but you improved your marketing just a little bit, revenue would go up in a hurry.

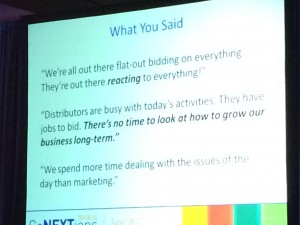

Alex shared that he took some time to learn a little about our industry in preparation for his presentation. He made some calls to distributors and asked some key questions to better understand what our “excuses” were to not investing more time in marketing.

Here are some of the responses he received:

“We’re all out there flat-out bidding on everything. They’re out there reacting to everything!”

“Distributors are busy with today’s activities. They have jobs to bid. There’s no time to look at how to grow our business long-term.”

“We spend more time dealing with the issues of the day than marketing.”

Alex urged us to be more proactive in lieu of reactive. Revenue growth and marketing are definitely proactive practices.

He also wants us to re-think the traditional marketing approach and move away from a products/services focus and toward a value based message. “Marketing is communicating your value to people who can buy it” Alex stated, “marketing is a transference of perception from you onto your market”

He explains that the way we think about our products/services is the way we market them. If we think we sell doors/frames/hardware our marketing material will convey that (boring) message. We might deliver a different message If we thought of ourselves as “improving the lives and companies of the general contractors we serve”.

I think we can all agree with this sentiment, you deserve more revenue! We know that the knowledge we have acquired through our years in this industry is unique and invaluable. We know that we provide a service to the construction team that is an essential part of a successful project. Where does this knowledge come into play, or more importantly why does it seem not to make a difference.

Alex asked for a volunteer from the audience to come up for a role play exercise. The volunteer would play the role of a contractor and Alex that of a distributor. Minutes into the exercise it became very clear that the main problem we (distributors and manufacturers) face is that there is a singular focus on price. The “contractor” reiterated time after time “I know you’ve done a remarkable job for me in the past, but you know I have to move forward with the lowest bid”

Alex asked for a volunteer from the audience to come up for a role play exercise. The volunteer would play the role of a contractor and Alex that of a distributor. Minutes into the exercise it became very clear that the main problem we (distributors and manufacturers) face is that there is a singular focus on price. The “contractor” reiterated time after time “I know you’ve done a remarkable job for me in the past, but you know I have to move forward with the lowest bid”

The “distributor” touted the valuable service he provides, the reliable deliveries, the excellent customer service but was shot down every time by the price objection. It was apparent that Alex was getting a little frustrated by this repeated objection. After the role play exercise Alex even commented that the volunteer was probably exaggerating to make a point. The expression of every face in the room said “no he wasn’t!”

While listening to the volunteer be adamant about the lowest price being the only consideration it made me question what role we play in this paradigm. It gave me a great idea for another blog post to further explain my thoughts, but for now just note that it was clear to me the volunteer as well as most distributors believe their value is of little significance in this scenario.

Don’t we want to try to change that? What if we follow Alex’s advice, even though we aren’t convinced it will make a difference. What if we are bold and confident that our service absolutely makes a difference and conveyed that message in our marketing materials? I think it’s worth a try, unless of course you are immensely satisfied with the balance in your bank account!

So, as eluded to above, the first step is to change your mindset about what you and your company does. Remember that your perceptions shape your marketing which ultimately shapes the market’s perception. (I believe this is what holds the power to change the above scenario.)

Second, put the focus on your value not your products and/or services. Remember that you do not sell doors and hardware, you improve the lives and companies of the general contractors that you serve. (By the way, you actually have to walk that talk!)

Third, Alex wants to dispel the Revenue Myth (this is an excerpt from his website)

The Fourth step is to make sure that nothing leaves your office without a testimonial on it. I have to say that I have been hearing a lot about the value of testimonials lately. I, for one, am willing to give it a try. But how do you get these testimonials. The thought of asking for one made me cringe. Thankfully Alex had an answer for that! He suggests a two step approach.

In the first step, you plant the seed. It can be as simple as calling your customer to thank them for their order. Let them know how important their satisfaction is to you and that you would like to call them back shortly after receiving their order to make sure all is well and get their opinion of the transaction.

This makes the second step a breeze. The customer anticipates your call and knows what to expect. He is more apt to have specific feedback to offer. Then all you need to do is thank him for his time and input and ask his permission to include his kind words (hopefully, that is what you rec’d!) on your website.

Snap! That sounds easy enough to actually pull off!.

I thoroughly enjoyed Alex’s presentation and plan to implement some of these strategies. If you would like more information you can visit his website at www.evangelistmktg.com.

Follow Me!